We conduct thorough inspections at every stage of the production process.

As one of the leading Inconel pipe manufacturers in India, Steel Craft Alloys operates a state-of-the-art manufacturing facility outfitted with advanced technology and staffed by a team of skilled professionals. This enables the company to produce Inconel pipes that consistently meet international quality standards and exceed customer expectations. Steel Craft Alloys' commitment to excellence is evident in the superior durability, corrosion resistance, and high performance of its Inconel pipe products.

| Pipe Specifications | ASTM A312, A358 / ASME SA312, SA358 |

|---|---|

| Tube Specifications | ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554 |

| Dimensions | ANSI/ASME B36.19M, ANSI/ASME B36.10M |

| Seamless Pipe & Tube Size | 1/2″ NB – 16″ NB |

| Welded Pipe & Tube Size | 1/8″NB TO 30″NB IN |

| EFW Pipe & Tube Size | 6″ NB – 24″ NB |

| Tube Outside Diameter | 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock |

| Thickness | 0.35 mm – 50 mm |

| Specialized in | Large Diameter Pipe Size |

| Schedule | SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, SCH 80S, SCH60, SCH80, SCH120, SCH140, SCH160, SCH XXS, SCH XS |

| Type | Seamless Pipes, ERW Pipes, Welded Pipe, Fabricated Pipes, Electro polished Pipe, Polished Pipe, Hollow Pipes |

| Form | Round, Square, Hydraulic, U Shape, Rectangular, Pan Cake Coils, Coiled, Hex, Honed, Etc |

| Length | Single Random, Double Random & Required Length. |

| End | Plain End, Beveled End, Treaded End |

Steel Craft Alloys is a leading manufacturer, supplier, and exporter of Inconel Sheets, Plates, and Coils in India, known for their outstanding corrosion resistance. These high-performance products are well-suited for a wide range of industrial applications. With a strong focus on quality and precision, Steel Craft Alloys delivers materials that meet exact specifications, earning a reputation for reliability and excellence in challenging environments.

Inconel Sheets are primarily composed of nickel (up to 72%), along with chromium (up to 17%), iron, and trace elements such as molybdenum, cobalt, niobium, and titanium. This specialized composition provides excellent resistance to oxidation and high temperatures, making them ideal for use in extreme conditions.

| Specifications | ASTM B168, B443, B670, B409, B424 / ASME SB168, SB443, SB670, SB409, SB424 |

|---|---|

| Dimensions | MSRR, AMS, BS, JIS, AISI, ASTM, GB, DIN, EN, etc |

| Size Range | Cold Rolled : 0.5-6.4 mm Hot Rolled : 3.0–10.0 mm |

| Thickness | 0.3 mm to 120 mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Tolerances (width / thickness | EN 10258/ DIN 59381 EN 10151 EN 10088 |

| Form | Sheet, Plain Sheet, Flat Shim, Flat Sheet, Shim Sheet, Rolling Sheet, soft annealed, descaled, sheared, annealed |

| Finish | 2B, 2D, BA NO (8), Cold rolled sheet (CR), Hot rolled plate (HR), SATIN (Met with Plastic Coated), No.1 finish hot rolled, 1D, 2B, No.4, BA, 8K, satin, mirror etc. |

| Hardness | Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Profiling | Plasma Plate Cutting Laser Plate Cutting Oxy-propane Flame Cutting |

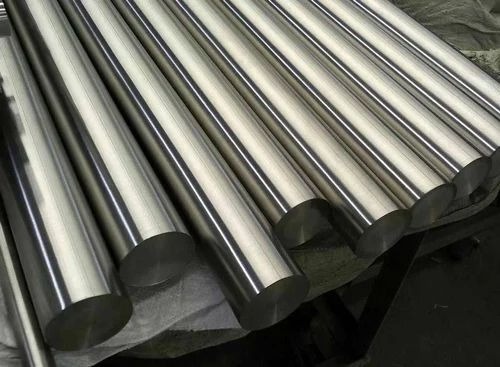

Inconel bars are advanced nickel-chromium alloy products prized for their outstanding resistance to high temperatures, corrosion, and oxidation. Primarily composed of nickel, chromium, and iron, these bars deliver excellent mechanical strength and durability, making them ideal for demanding industries such as aerospace, chemical processing, and marine engineering. They retain their structural integrity across a wide temperature spectrum—from cryogenic levels to extreme heat—ensuring consistent performance in the harshest environments. Their superior resistance to corrosive agents, including acids and seawater, further enhances their longevity. Inconel bars are widely used in manufacturing components like valves, fasteners, and gas turbine parts, and are recognized for their reliability and endurance in critical applications. Their strength, versatility, and resilience make them a top choice for industries requiring high-performance materials.

| Specifications | ASTM B166, B446, B637, ASME SB166, SB446, SB637 |

|---|---|

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Bar Diameter | 3 ~ 800mm |

| Hex Bar size | 2-100mm A/F |

| Flat bar size | Thickness: 2 -100mm. Width: 10 to 500mm. |

| Square bar size | 4 to 100mm |

| Rectangular Bars | Size: 33 x 30mm to 295 x 1066mm. Thickness: 3.0 to 12.0mm. |

| Hollow Bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID |

| Billet Size | 1/2 to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Bars Condition | Hardened & tempered, annealed |

| Cold Rolled Bar Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

Steel Craft Alloys is a renowned name in precision manufacturing, specializing in high-quality Inconel Pipe Fittings. Inconel, a family of austenitic nickel-chromium-based superalloys, is celebrated for its exceptional resistance to high temperatures, oxidation, and corrosive environments. Our expertly engineered Inconel Pipe Fittings harness these superior qualities, making them the preferred choice for demanding industrial applications.

Steel Craft Alloys provides an extensive range of Inconel Pipe Fittings across multiple grades, each tailored to meet specific operational needs. Popular grades include Inconel 600, Inconel 625, Inconel 718, and Inconel 825 — all carefully selected for their distinct chemical properties to ensure peak performance in a wide variety of environments.

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM B366 Inconel Buttweld Fitting |

| Type | DN15-DN1200 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Inconel Pipe Fitting |

| Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Connection | Welding |

| Manufacturing process | Forge, Cast, Push, Press, etc. |

| Key markets and industries |

|

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Specialized manufacturer of | 90 Deg Elbows, 45 Deg Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End, Pipe Bend |

Steel Craft Alloys is a renowned leader in the manufacturing of premium Inconel Flanges. With an unwavering commitment to quality and innovation, our dedicated website reflects our deep expertise in this specialized field. Inconel, a nickel-chromium-based superalloy, is celebrated for its outstanding corrosion resistance, high-temperature strength, and durability—key attributes that form the foundation of our flange manufacturing.

Our extensive inventory features a wide selection of common grades of Inconel Flanges, each carefully engineered to comply with rigorous industry standards. Among the notable grades we offer are Inconel 600, 625, and 718, each possessing distinct properties tailored for specific uses. For example, Inconel 600 delivers excellent resistance to heat and corrosion, making it perfect for high-temperature settings. Inconel 625 is highly valued in marine and chemical processing industries due to its superior strength and resistance to pitting and crevice corrosion.

| Standard | ASTM B564 / ASME SB564 |

|---|---|

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Size | 1/2" (15 NB) to 48" (1200NB), DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| JIS | 16 K, 5K, 10 K, 20 K, 30 K, 40 K, 63 K |

| Flange Connection / Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove, Flange Pipe. |

| Types of Flanges | Threaded / Screwed / Forged / Plate |

| Coating | Yellow Transparent, Zinc Plated, Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized |

| Test Of Flange | Direct-reading Spectrograph, Ultrasonic flaw detector, Magnetic particle detector, X-ray detector, Hydrostatic testing machine. |

| Production Technique Used | Heat treated, Forged and Machined |

| Equipment | Press machine, Bending machine, Pushing Machine, Sand-blasting machine, electric bevelling machine etc. |

| Test Certificates | EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc |

Steel Craft Alloys is a leading manufacturer, supplier, and exporter of high-quality Inconel fasteners, offering an extensive range designed to meet the most demanding industrial requirements. These fasteners are crafted from a nickel-based superalloy known for its exceptional strength and resistance to high temperatures.

Inconel fasteners are primarily composed of nickel, chromium, and molybdenum, with the addition of niobium to enhance strength. This specialized alloy delivers outstanding resistance to corrosion and oxidation, making it ideal for use in high-temperature and harsh environments. Our cutting-edge manufacturing techniques ensure precise integration of these elements, resulting in fasteners that perform reliably across industries such as aerospace, chemical processing, and other challenging applications.

| Standard | ASTM B166 / ASME SB166 |

|---|---|

| Bolt / Screw Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Nuts Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Washers Size | M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Machine Screws Size | M1.6 – M12 |

| Self Tapping Screw Size | No.2 – No. 14 |

| Length | 3 mm to 200 mm |

| Threads | UNF, BSW, BSF, METRIC, UNC, or as required |

| Fasteners |

|

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Raw materials Source | JSPL, Mukund Steel, Tata Steel, Dhamm Steel, Usha Martin,etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production Process | M24-M100: hot forging , M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Types | Bolts, Nuts, Stud Bolts, Washers, Threaded Rod, Anchor Fasteners, Eye Bolt, Stud, Cotter Pin, Socket Screw, Fine Fasteners & Spares, Foundation Fasteners, Hexagon Castle Nuts, Hexagon Domed Cap Bolts, Hexagon Thin Nuts etc. |